How to Choose the Right Warehouse Racking System? A Complete Guide to Doubling Your Storage Efficiency

When planning or upgrading your warehouse, understanding the different types of racking systems is the first step to success. Each system is designed to meet specific storage needs, cargo types, and access frequency requirements.

1. The Heavy-Duty Workhorses: Pallet Rack & Heavy Duty Rack

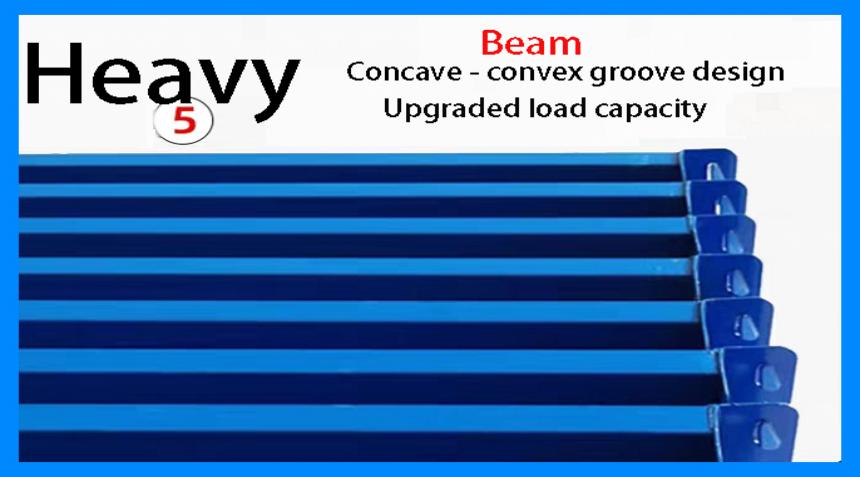

Pallet Rack is one of the most common and versatile racking systems. It allows direct access to every single pallet, making it ideal for warehouses with a high variety of SKUs and lower batch quantities. Its structure, typically made from steel rack uprights and beams, offers exceptional load-bearing capacity, making it the go-to solution for heavy duty storage tasks.

Heavy Duty Rack is another term for pallet racking, emphasizing its superior carrying capacity. These systems form the backbone of most industrial warehouses, safely storing large volumes of raw materials and finished goods.

2. The Pioneer in High-Density Storage: Shuttle Rack System

When land costs are high, and you need to maximize the use of existing space, the shuttle rack with shuttle car stands out. This is a semi-automated, high-density system:

How It Works: A radio-controlled shuttle car operates on rails within the rack structure, automatically storing and retrieving palletized loads.

Key Advantages: It drastically reduces aisle space, offering a much higher storage density than conventional pallet racking. It also reduces the need for forklift operation, enhancing both safety and productivity.

Ideal For: Storing goods with relatively low SKU variety but high volume, such as in the food, beverage, and cold chain industries.

3. Flexibility & Specialized Solutions

Not all warehouses store standard palletized goods. For specialized needs, consider these dedicated systems:

Cantilever Rack: Designed specifically for long, bulky, or irregular items like steel pipes, timber, panels, and plastic granules. Its unique arms provide unmatched accessibility, making it the preferred choice for manufacturing and construction material industries.

Light Duty Rack: This category often includes steel shelves and lighter metal racking systems, used for storing boxes of parts, components, or documents. They are perfectly suited for assembly workshops, retail stockrooms, or office storage areas.

Mezzanine Rack & Steel Platform: If your warehouse has high ceilings, mezzanine racking and steel platforms can effectively create additional storage or workspace. They function like a "second floor" built within the warehouse, perfect for offices, packing areas, or storing lighter goods, effectively doubling your available space.

4. The Core of the System: Material & Design

Regardless of the type you choose, the core of any system is durable steel storage material. A high-quality metal racking system should feature:

High-Quality Steel: Ensures structural integrity and a long service life.

Professional Design: Based on precise calculations considering your warehouse layout, floor load-bearing capacity, and cargo weights.

Surface Treatment: Powder coating or galvanization to resist the potential moisture and wear found in warehouse environments.

Conclusion

Selecting the right warehouse rack is a strategic decision. From basic steel shelves to sophisticated automated shuttle rack systems, the key lies in accurately assessing your goods' characteristics, access frequency, and future growth needs. By investing in the correct racking system, you not only ensure the safe storage of your heavy duty goods but also optimize workflows, transforming your storage space into a genuine competitive advantage.

Need Expert Advice? Our specialist team is ready to provide you with a free warehouse layout design and solution consultation!